A Sprocket is ordinarily a wheel with teeth that lock onto a chain. When the Sprocket turns, the teeth hold the chain and move different parts joined to the chain. This activity gives straightforward and controlled rotational development of enormous gear and hardware. A piñones taper is fabricated with metal or built-up plastic to deal with the power of the moving chain. These parts are contrasted with bags, which serve a similar wheel-molded plan with teeth.

Sprockets connect with an assortment of chainrings or dissimilar to gears which interlock together to move rotational development. Rather than gear frameworks, most piñones taper work in bike chain congregations. Sprockets are parts made with explicit chainrings to fit and deal with clear loads accurately. Picking erroneous sprockets can cause serious misfortune, and teeth will chip or break. Then again, the sprockets in their chains can move without breaking, even in uncompromising transport framework applications.

Sprockets are ordered by type A, type B, type C, and type D, which are portrayed underneath:

1.Type A

This Sprocket is level and has no center on it. These are regularly mounted on the ribs or center points of the gear. They pass through a progression of openings that are plain or slim.

2. Type B

This Sprocket is made with a center point on one side. This permits the Sprocket to fit near the hardware on which it is mounted. Because of this, it lessens a huge shade load on the hardware’s orientation.

3. Type C

Type C sprockets are made with a center on both sides of the plate. It is regularly utilized in such applications where the pitch distance across is enormous, and there is more weight to help on the shaft. Bigger burdens require greater centers.

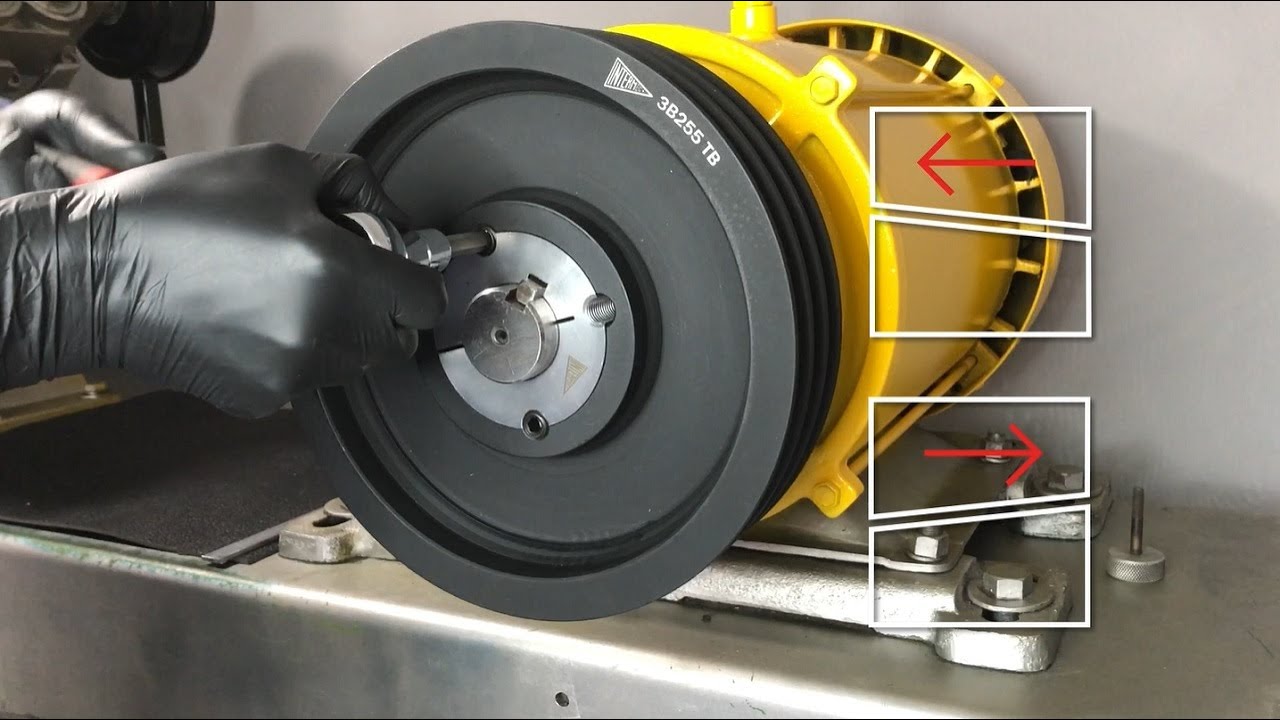

4. Type D

These sprockets utilize a Type A sprocket mounted on a strong or split center point. The Sprocket is effortlessly supported for expulsion and darted to the center. Don’t bother eliminating direction and other gear because the speed proportion can be changed without it.

Uses of Sprockets

A few kinds of Sprocket accessible, each applied on various sorts of hardware to run on development in different applications. Following are the normal utilization of sprockets: The sprockets are utilized in rural and cultivating gear applications. These are additionally utilized in auto gear. It is used in chain-driven apparatus, for example, transport lines and other processing plant frameworks.